I’ve created a playlist for my videos on the awesome blackbox sampler/sequencer from 1010music.

I’ve created a playlist for my videos on the awesome blackbox sampler/sequencer from 1010music.

Here’s a handy playlist of my Adafruit project video series:

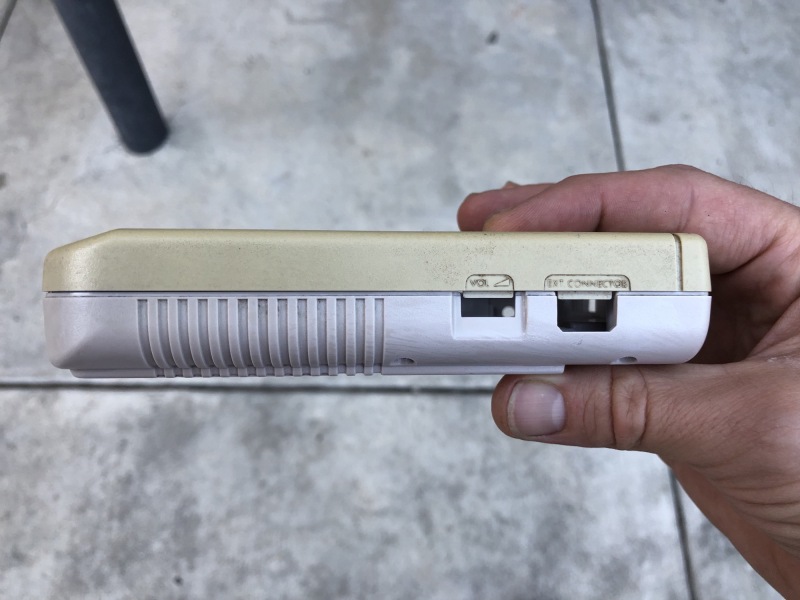

I soldered a TRS 3.5mm audio jack to the direct line level stereo output of my Game Boy DMG. Wow does it sound richer and beefier (technical terms)! Still responds to the volume pot and I may have recorded this a bit hot.

Audio recorded from Game Boy to Alesis mixer. I didn’t change the volume dial on the GB when I swapped the cable between outputs, so the volume difference is inherent between them.

I followed this page for guidance: https://snapguide.com/guides/mod-your-dmg-gameboy-with-prosound-stereo-jack/

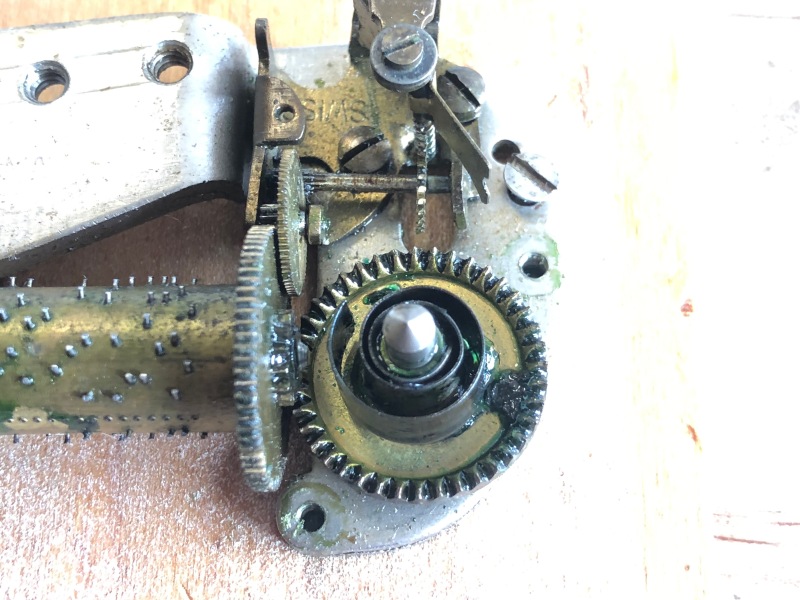

This music box movement comes from a family heirloom rocking rooster (like a rocking horse) that I believe my dad had when he was a kid in the late 1930s – early 1940s. The music box stopped working long ago. With the advice of my friend and automaton builder/clock repairman Dug North, I intend to restore it to it’s former glory.

The music box mechanism itself was made by Thorens of Ste. Croix, Switzerland.

So far, I’ve loosened up the parts with sewing machine oil and then some WD-40. I used a pick and a wooden pointed dowel to scrape out come green gunk — possibly corrosion and old lubricant? — and now things are moving a bit.

Dug advised me to remove the comb before tackling the mainspring, in case the spring was wound and bound and could potentially unleash some fury on the drum causing damage to the comb.

Sure enough, the mainspring is broken. Time to get a replacement.

The Moog Drummer From Another Mother is a sweet drum synthesizer with 8-step sequencer built in. It’s semi-modular and plays well with other modular gear. I like it!

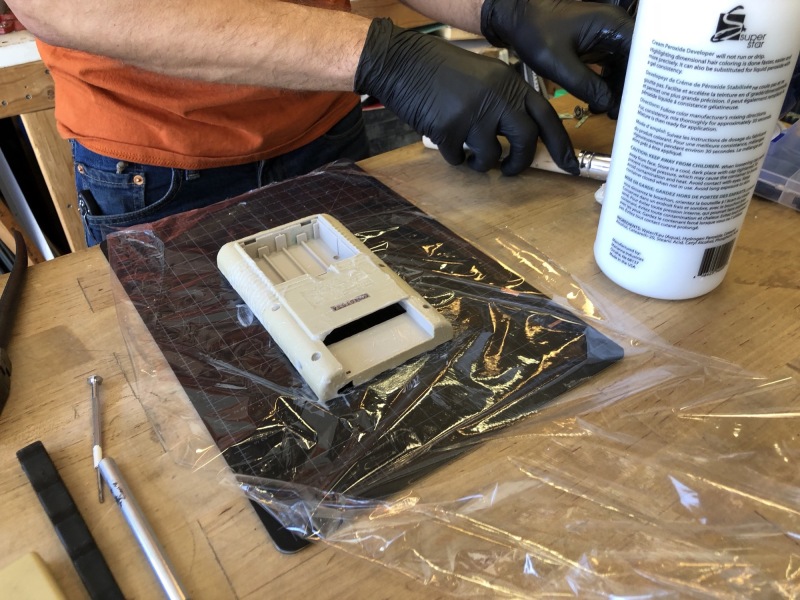

I got this launch edition 1989 Nintendo Gameboy at a yard sale for $1 and decided to restore it and clean it up. First, I needed to re-solder the battery connectors to the PCB so it would start up. Then, I cleaned out the cartridge slot so it would actually load games. The yellowing on the case was pretty gnarly, so I took it fully apart and used the hydrogen peroxide + UV light method to reverse the ageing. It worked great!

The basic chemistry of it, as detailed in the retr0bright project page, is that there was bromine added to the ABS plastic to act as a fire retardant. Over time and exposure to UV light, the bromine finds its way to the surface, lending the yellow cast. Hydrogen Peroxide, and activator, and more UV light finish the job and allow the bromine to fly free, leaving the surface of the ABS entirely.

Here you can see the front of the case after ageing for 29 years next to the back of the case after the hydrogen peroxide + sunlight for six hours treatment.

You can search for the exact method and different recipes online, but you essentially need a high-ish concentration hydrogen peroxide — here I’ve got 20 volume which is 6% concentration — and an activator such as Oxy and something to thicken it. People call this Retr0brite. It turns out that salon-grade hair “bleach” has all of the necessary ingredients rolled into one bottle.

Paint it on (after cleaning the case with water and rubbing alcohol and more water), seal it up in cling wrap, and put it in the sun for six hours.

What a difference!

Here, I’ve gotten the top half going. I didn’t leave it in the sun for as long and may give it another shot to further remove the yellowing.

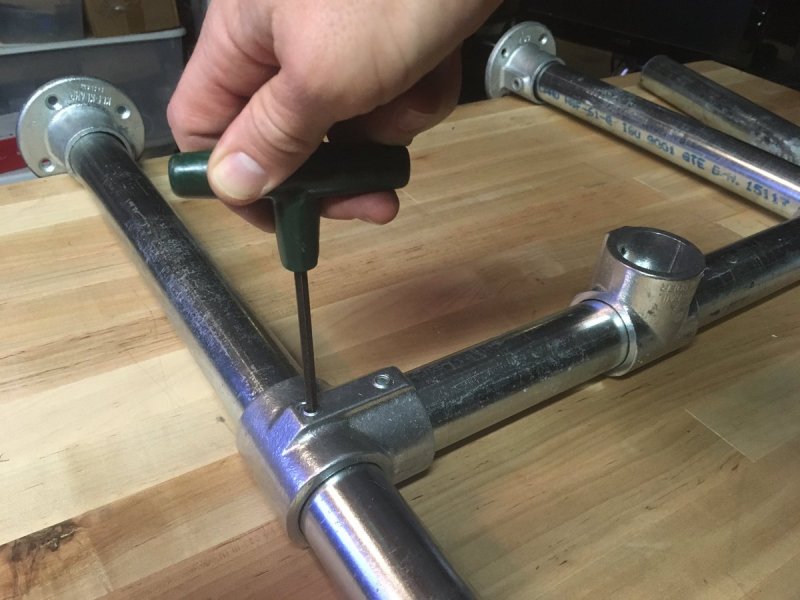

I designed and built this lovely standing desk a few months ago — these are the build photos.

My materials of choice were galvanized pipe, SpeedRail and Kee Klamp connectors, four heavy-duty locking casters, and a maple butcher block top.

I use it for my computer workstation in my workshop — it’s nice to be able to roll it around when needed. It would also make for a very nice workbench or kitchen prep table.

The top is 48″ x 30″ x 1-3/4″ thick. The legs are 34-1/2″ tall, so including casters and butcher block top, it stands at 38″ high.

Here’s a quick DIY for making handbalancing canes. My daughter and I built these in an afternoon. They’re great for working on handstands, press-ups, L-sits, dips, and handbalancing tricks. We use them during aerial straps classes at Cirque School LA, so I thought it would be fun to make a set at home.

Parts:

-One 2’x’2′ piece of 3/4″ plywood (we started with pine, but that was too soft) cut down to three sections

-Two 4″ lengths of 2×4 for hand blocks (I used some scrap framing pulled from our 1939 house during a renovation)

-Four 3/4″ floor flanges

-Two 18″ sections of threaded 3/4″ black pipe (you can choose 12″ for a shorter stand, and can always swap them out later)

-Twelve #10 1-1/2″ screws

-Sixteen #10 3/4″ screws